GDO = Garage Door Opener.

I decided to just go for it and installed the electric for the door opener before even testing it under power.

The fact that the ceiling is mostly air means some slight shenanigans are required for running a cable across it. Conveniently, there were already these angle struts mounted for other purposes, to which I could simply zip-tie the power cable. And so it was.

But of course before anything may be done, something else must first be done. In this case, it was our old friend “there’s no finished wall where you want to run some power cables”. Fortunately, it was only a short span required and I had suitable plywood on hand that was easily reached.

Moment of truth…

OV = Office View.

This is what the office looked like when I moved into it last week.

There’s still trim work to do and I plan to make some nice built-ins to take the place of these indoor/outdoor tables, but at least for now, I have a heated, separate place to have my office stuff and, at long last, I can spread out a bit and leave it all set up. More gear appeared on the tables since this pic was taken. The table on the left (with the red crate) is where the soldering/surgery station was set-up. That coil of cable on top of the power center that isn’t actually going anywhere is destined for the generator port, which hasn’t been installed yet. I obviously need to cut some ceiling tiles and close that up, too.

See that piece of drywall at the bottom of the door? That’s a draft guard, or so I thought, until I did a thermal inspection. Recall the last post – the floor was VERY cold.

IRC. Infra-red Camera (not Internet Relay Chat).

Curious about why the floor was cold, and keen for a new toy, I bought an infrared imaging camera. This one takes both visible and IR images and overlays them, which makes it especially easy to understand the context of the thermal image. Without the visible overlay, regions of similar temperature would be indistinct in the thermal view and thus make it hard to correlate with the physical scene. With the visible overlay, it’s all right there. So what did I learn?

For starters, I learned that the drywall fragment wasn’t doing much for me at all. For the most part, it was simply redirecting the draft up the face of the door (and still into the room)! With this knowledge, I went right out and acquired a rubber door sweep — a flexible footer for the door bottom that stops the air flow under the door. That worked nicely (picture at right). Notice the cold strip right under the door but there’s no cold spray in front of it. There we go. That helps.

You can also see some cold around the jamb of the door. Not a lot of airflow there, but some, and definitely it’s cold. Since this is technically an interior door, there’s really no accommodation for weather stripping on the jamb. I will need to add some auxiliary trim parts to which I can affix some weather stripping to seal these edges, too. I took a closer look at the door and indeed, it doesn’t fit especially snugly in its frame and isn’t actually flat, either – it bows a bit. This is not really a problem for an interior door – it closes and stays closed okay – but since the space behind it (the mud room) is unheated, it matters. With the thermal imager, I’ll be able to verify that my mitigation works.

I am also pleased that the door face itself wasn’t too cold. I did get a solid core door just for the feel of it, but at this point I’m also glad for its insulative properties, as well. For the curious, the blue crosshair is the coldest spot in the scene. The red (upper right, mostly out of frame) is the hottest. The green inverted X marks the center-of-field temperature. The captions Max, Min, Cen (center) label the corresponding readings.

With the door sweeps (two of them – there are actually two doors to this space) in place, the comfort in the room was greatly enhanced. No more frozen ankles. I also realized there were some other things I could do to increase comfort.

First, while I don’t have battery capacity to run an electric heater, if the battery is full and the sun is out, there is enough sunshine to run an electric heater! I can thus save on propane (yay) when the sun’s out, and that’s worthwhile, for sure. Also, running a fan from the floor pointing up (through the electric heater, if in use), circulates the air and equalizes the temperature decently, also keeping my feet from freezing.

For fun, I aimed the thermal imager elsewhere in the office and learned some more things. I learned that the temperature difference between the insulated bay between the studs and the studs themselves is enough to be resolved by the imager. You can even see the screw heads (dark blue circles).

I also proved that the DriCore flooring with its foam blocks is actually doing a pretty good job of keeping the cold of the concrete beneath it beneath it. However, at the edges of the subfloor, where I have not yet installed base trim, there is definitely a place for cold air to come in. There’s no blue spray here, so this doesn’t represent air flow per se, but a cold spot is a cold spot and surely covering this so there’s no air exchange even possible with the cold concrete space seems like a good idea, even if not an urgent one.

WL = Workshop Lighting.

After the office and the garage door opener, the next priority for electric power is workshop lighting. It occurred to me that the same lag-eye bolts that I used for the suspended ceiling in the office would be perfect for hanging some lights — especially since I have this driver chuck for them that makes it super easy to just send them into the roof truss bottoms. Of course, it turned out that the perfect spot for one of the lights required putting a hanger right where the edge of the roof interior access panel was. That meant I couldn’t drive a lag-eye there. I could, however, just drill a hole in the trim that was there already and just hang it from there 🙂

When I’m certain I like the positions of the lights, I’ll trim those hanger chains.

What you can’t see in these pictures is that it’s about 20F in the workshop while I’m doing this, at 10ft in the air atop a ladder. Driving lags into the ceiling can be done with thermal work gloves (and was!) but making the electrical connections required more dexterity than that, so it was gloves off for those tasks. Also challenging was putting the little screws for the cover plates back in, upside down (against gravity), on a fixture that’s now swinging, with frozen fingers. What’s more amazing is that somehow I managed to stay on the ladder through all those shenanigans.

I have developed a stance on the ladder that’s especially good for this kind of thing. I rig my ladder for A-frame (I do love articulated ladders) and actually straddle it, turning my feet in pigeon-toed a bit. This locks my feet into the ladder, gives me stability left-right as well as front-back (the ladder has splayed feet to assist with that), without having to do too much thinking. It automatically centers me over the ladder and it’s hard to accidentally step off.

From this position, one can also simply sit on the top of the A-frame, if that’s needed. Through all of this, it wasn’t just my hands that got cold. My feet did, too. Either from the frigid aluminum ladder or the frigid concrete floor.

And with all that, presto, a dimly lit disaster area becomes… a brightly lit disaster area!

I found some nice 15000-lumen LED hi-bay lights that used only 110W each. For all that light, that’s not a ton of power, really. I don’t know if I’ll even need task lighting over my machinery (once the machinery is moved in). 440W for 625 square feet well-lit? Sounds pretty good to me.

I bought two more of them for the garage (not installed yet). The storage hall in the workshop will get something smaller and on a separate switch, since that’s only occasionally visited space and too small to justify one of these floods. The tidy room, likewise. It’ll probably get one or two 2×2 LED panel lights like I used in the office.

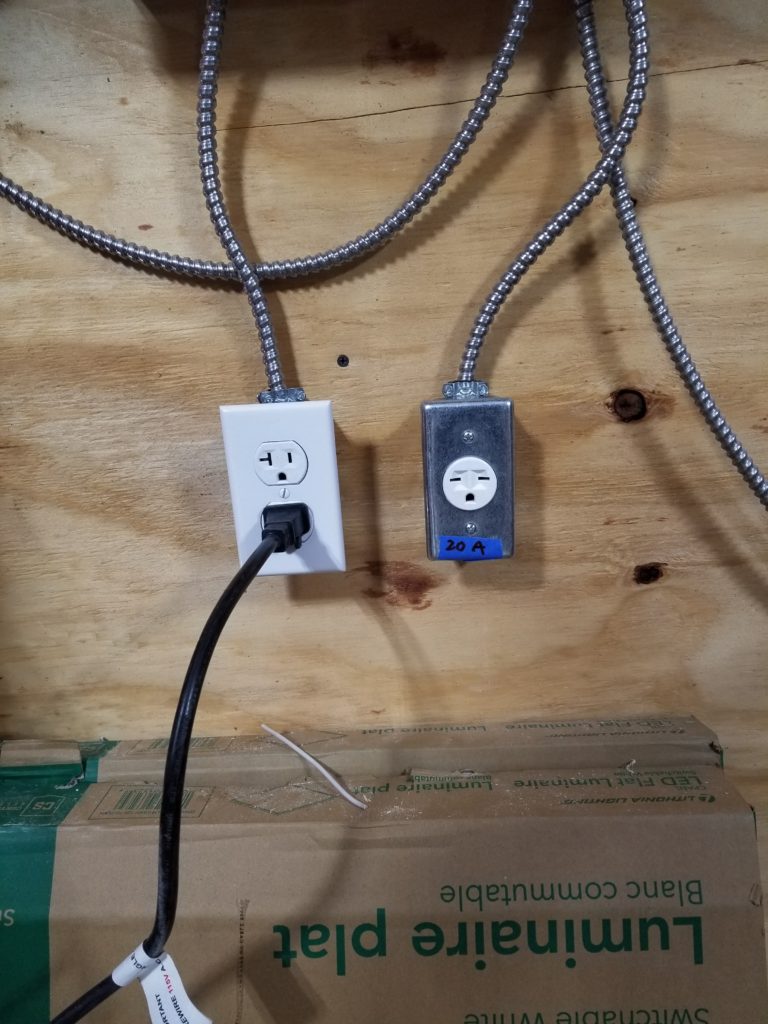

While I was wiring, I took a quick diversion to install two outlets actually in the workshop proper so I could stop running extension cords into the office. Proper power distribution will be done when I figure out where all the work stations will go, but for now, at least, there’s just power to be had if I need it. I made sure to include a 240V outlet for the table saw, which I’ve been wanting to use for quite some time now. I don’t quite have room to move the table saw into the shop yet, but soon I will. I wonder if the designers of the outlets made them look like faces on purpose. And metal vs plastic cover? I had the plastic cover already in stock…

Smoboke.

I’m of the opinion that we can love the art, even if we don’t love the artist. In this case, “smoboke” is a reference to a bit by Bill Cosby, who had an especially lively take on being in the dentist’s chair and noticing smoke arising from his mouth as the dentist drilled. Distraught, but unable to speak properly because of the suction line in his mouth and numb lips, he tried to alert the dentist by saying “smoke!” but all that he could manage was “smoboke!”. After a few earnest pleadings of “smoboke”, he makes the leap and cries out “FIBER!” (fire).

And, indeed, FIBER! Not fire, but fiber. Optical fiber. Mine is now installed and in a flash, I have 900% more internet speed than I had before and quite a bit more reliability (presumably – it’s only been on for a few hours at this point).

I am glad to let go of my cellular data provider and the Rube-Goldberg device I had to frankenstein together to make it work. I am sad that I’ve invested about $1000 in the cellular solution, only to find it was no solution at all, but so it goes. Sometimes what we learn is expensive to learn.

It turns out they had to install an extra utility pole to run my line. I was impressed that snow and frozen ground didn’t slow them down at all. They just went right to it and got it done rather quickly, actually. This clever boom truck could wield its auger or stow the auger and grab a pole with pinchers, all from the comfort of the control seat.

Once the hole was dug and the pole planted in it, they used a hydraulic tamper to pack the earth around the hole to keep it snug. Then it was a little quality time with the bucket truck to string up the fiber line itself.

Before the day was done, this little box was attached to the side of the W.O.G., waiting for the installer to bring the fiber into the house and make it go. It turns out the inside equipment was really quite minimal. Just one little black box that fits in the palm of my hand (though my hands are big). A wire from there to my mesh network router and my homestead wifi is up and running, now 9x faster than before.

Before we leave the fiber segment, I just want to show you this, which was on the back of one of the utility company trucks.

There may be something to say about this, but words fail me.

EMWTTT = Even More Water Trouble, Times Two

Yup.

Again.

But different.

But again.

Water trouble #1 was a fine day recently I turned on my well pump to refill my freshwater tank and… no water came! Now, most of the supply pipe is below the frost line (which is good, because it’s been below freezing for weeks) and the whole run is supposed to drain back into the well when I turn the pump off, purging it all back to air, so there’s nothing in there to freeze. That was the plan. But this day, no water comes. The inverter goes THUD when I switch on the pump, which it always does as a 1700W load appears instantaneously. So that’s good – the pump is getting power. But no water comes. It’s usually 45s or so before the water gets here, always preceded by some gurgling sounds. This time, none of that. A minute. Two minutes. Nothing. Shit.

In a little bit of a panic, I start thinking about how I might function without a water supply. There are ways, but they are definitely inconvenient. Imagine buying a set of eight 5-gallon office jugs, pumping them each into the freshwater holding tank, then doing it all again every 4 or 5 days. No thanks. Do-able, if I had to, but I sure don’t want to have to. Thinking there must be a problem in the well, I call my excavator guy (not because he’s the well guy, but because the well guy is his guy and I can’t find the well guy’s contact info). Curious, he asks me to describe the situation, which I do. He’s satisfied it’s not a problem in the well most likely. Can I snake the line, he asks? See if there are any obstructions, even though it’s supposed to be freeze-proof? A valid question. I have a snake line but it turns out it can’t go around some tight corners that are in my fresh water intake line. It occurs to me, though, that I could just disconnect that intake line from the well supply pipe and blow in it — if it’s blocked, I’ll know. And if it’s not, I’ll know that, too.

The place to access this is under the Propane Porch, which is a bit snowed at this point. I have snow pants – somewhere – but still in an anonymous box, so that doesn’t help me. I basically need to lay down in the snow to do this and I don’t much care to get cold and wet in the doing. It dawns on me that I could put something down between me and the snow, so I do that. It’s nothing fancy, but this sheet of plywood will do just fine to keep me from actually laying face down in the snow while I fuss under the porch to access the water line.

Disconnecting a line that was meant to stay put, in sub-freezing temps, takes some doing, but I get it done. I give the inside line a mighty puff. And something very interesting happens! There is significant resistance, then it clears. There was water in that line! Excavator thinks what I had was an air lock. He’s probably right. It occurs to me that when I’m paying attention, I actually hear glug-glug when the supply line is draining back after a fill. That means it’s not draining smoothly. And that’s probably exactly how the air lock happens. There’s a cleanout cap on the fresh water tank that isn’t air-tight. That’s enough to let the air pressure out when the tank fills and it’s mostly enough to let the line vent as it drains back, but at this point I’m thinking it’s not really enough for that vent and that’s the problem. Next time I fill the tank, I will open that cap fully and listen to the drain-back. If it still glugs, then I need to add some venting elsewhere in the system – or simply plumb in a tee in the middle of the offending area that I can use to blow it free if it locks again 🙂

Once I had the line cleared, I turned the well pump back on and listened at the supply pipe. Gurgles suggesting water is on its way! Yes! It’s not the well at all, just like he thought. Excellent. Before I make an icy mess under the house, I switch off the pump and re-connect the supply to the house. Then I fill the tank without incident. I did not think to listen for the drain that time, though.

Water trouble #2 became evident when I went into the loft to decommission the cellular hotspot I was using for internet service, now that I have the fiber line. I noticed the area under the HRV wet. A lot wet. All the wet was under the flooring mats, but wet it was. And had clearly been this way for a while.

I did a bleach treatment and put a bowl under the HRV to catch the water until I can figure out the best solution.

I opened it to see where the water was coming from. It’s supposed to drain out the vent pipe.

Water was dripping onto the floor of the compartment, which as you can see is angled toward the vent, but instead of trickling out the vent pipe, it’s dripping down the wall behind the unit. There’s really not a tight seal between the housing and the wall, so it’s not surprising there might be a gap between the back end of the housing and the exhaust pipe, though good design would have had them nest in such a way that a seal would not be required, as long as there was a drain slope. When there’s more light, I’ll inspect this more carefully and see if the answer is driving some screws to cinch the housing against the wall more tightly or if I need to add some kind of sealant in there. The HRV has been doing very well in the cold, dry weather – the inside of the house is nice and dry now – so if I have to turn it off for a day to dry it out before applying some sealant, that’s not going to be an issue. I’ll have to look closely, though, to see where the water is dripping from as well, to be sure that the sloped pan is going to catch it (and direct it where I want, once sealant is applied). There’s some water on the front of the box here, but I don’t know if that was just caused by splashes as I opened it or is actually finding its way there. A more lengthy investigation, while it runs, in daylight, is required. It is not, however, urgent – the water seems to be finding its way out in one spot, under which I have placed a bowl to catch the water. If that’s really the only spot, the floor will dry out and I’ll know it. If there’s a leak behind the unit, the floor will continue to get wet and I’ll know that, too. I’ll give it a few days to see what changes, then go after it.

RB = Random Bits.

Sometimes, it’s the little bits of completion that help make a space feel more settled. In this case, simply mounting the fire extinguisher in the BeDiLiA to the wall made it look more purposeful, as well as no longer being a foot hazard. I am actually surprised at how much better that corner looks with the floor clear and the extinguisher on the wall. Like I said, sometimes it’s the little bits of completion that make a space feel better.

After getting a face full of ash while blowing into the wood stove to encourage some coals to glow and re-ignite, I remembered a trick I learned some time ago: use a blow pipe! I found this section of copper tubing that previously carried propane into the W.O.G. but had been replaced with a more intelligent approach. After I (mostly) straightened it out, it was perfect – already just the right length to get deep into the stove and keep my face clear. It also lets me direct the airflow quite precisely and its narrow bore means a forceful stream is possible if I want it. I’ve also seen 1/2″ copper pipe used, with an end cap soldered on, with a small hole drilled in the end cap to provide a small, forceful air stream.

When one has a compost toilet, there’s really no need for a separate container for compost from the kitchen. I just toss my kitchen scraps right into the toilet bucket. There was one time, though, that a couple of egg shells landed on some previous TP such that when I next went to the T.H.R.O.N.E. to do some business, I happened to notice this googly-eyed scene:

…which gave me a smile. I don’t think I’ve ever had a toilet bowl smile at me before.

Quiche.

Yup. Quiche.

This piece of quiche right here, in fact:

And what is the significance of this slice of quiche, you ask? It’s this: two Sundays ago, when I was at my usual venue for their breakfast buffet, the server (who either that time or the time before had learned my name) happened to notice I had enjoyed a slice of quiche but left the mushrooms on the plate. She offered to make me a slice without for next time. I thought that was really sweet — and excellent customer service — and I thanked her for her kindness but said she didn’t need to go through any trouble. I could get around the shrooms easily enough.

The next week, there I am enjoying my breakfast and the server comes to my table and says “I made you a special slice of quiche – no mushrooms”. She excuses herself to the kitchen and returns promptly with this. One slice of fresh, home-made quiche, no shrooms, just for me, hand-delivered. Now that is how you show your customers they matter to you.

My previous employer had an on-site cafe where the chef got to know the preferences for each of the employees. There were usually just one or two choices for lunch on any given day, but if there was some ingredient that was problematic, we could just tell him and he’d accommodate us as best he could. It didn’t take long for him to learn how we liked it. Going up to the counter and having him point at one and say this one is yours, and noticing the bleu cheese had been swapped for cheddar crumbles because he knows I don’t like bleu cheese, now that was great service. After just a few weeks, I didn’t even have to ask. He remembered what I liked/didn’t and would adjust my serving accordingly. He did that for everybody and it was awesome.